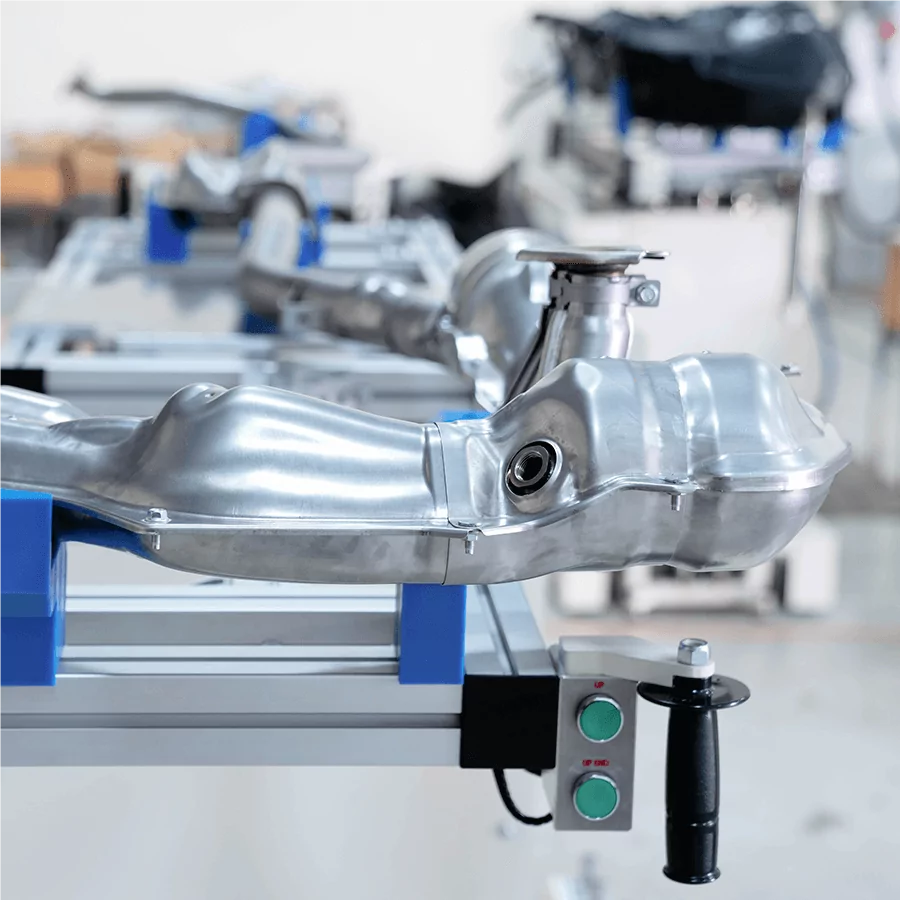

Solutions

Stainless Steel Grades

Austenitic

They are iron, chromium, nickel and carbon alloys. Adding nickel modifies the structure of these materials.

This is the stainless steel group with significant benefits for manufacturing components and equipment, as well as service performance. They have excellent forming properties, great corrosion resistance and are very easy to weld.

Ferritic

Ferritic stainless steels are also iron, chromium and carbon alloys, with higher chromium and lower carbon content than martensitic stainless steels. The typical values of these elements are C < 0.10%, Cr 16 – 18%.

Duplex

Duplex stainless steels are microstructurally constituted by two phases: ferrite and austenite. As alloying elements, they contain iron, chromium, carbon and nickel, with the latter being at a lower percentage than in austenitic stainless steels.

In general, they have higher mechanical properties and corrosion resistance than ferritic and austenitic stainless steels.

3CR12

3CR12 – Is a corrosion resisting steel, which was developed by Columbus Stainless, to fill the gap where other ferritic grades underperformed. This material is a tough, weldable steel that is often the preferred

material in applications where wet abrasion occurs. It can be readily painted, offering the advantages of a coated system with additional protection.