The 3CR12 Electrification Masts Case Study

Corrosion is the natural, gradual deterioration of metals reacting with their environment. It degrades the useful

properties of metals and structures including their strength and structural integrity. In the ambient environment,

most metal alloys tend to revert back to their natural stable states. Carbon steels, for example, are made up of iron

and a combination of other alloying elements. Without any additional surface protection, they tend to form a layer of

rust (iron-oxide); which is brittle and exfoliates, exposing a new fresh layer of steel to be attacked. This cycle

continues with devastating effects to equipment and structures due to resultant loss in through-thickness and

inevitably causing perforation – and low life.

When choosing metals for longevity and low maintenance, stainless steels become the obvious choice. Stainless

steels selection is primarily concerned with corrosion resistance in a particular environment. Aesthetics is often

important and thus the ability of the stainless steel to resist discolouration becomes critical. Cleanability and

hygiene considerations may dictate the stainless steel finish along with aesthetic considerations.

Stainless steels have a unique advantage in that a thin, tenacious and self-repairing passive chromium oxide layer

forms on the surface of the steel. This oxide layer gives the steel its characteristic corrosion resisting properties in

most environments. The steel must contain at least 10.5% chromium for this passive layer to form. Stainless steels

are known for their superior corrosion resistance and mainly used in the bare mill finish without the need for

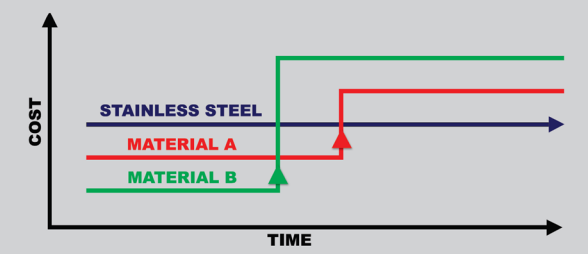

additional protective coating systems to enhance corrosion protection. This brings into consideration a concept

known as Life cycle costing (LCC) – which takes into consideration the initial material input cost, fabrication costs,

maintenance and refurbishment costs, cost of lost production due to downtime and possible replacement cost over

a defined products’ lifespan. Stainless steels generally have higher input cost compared to some competing

materials; however, because of the characteristic corrosion resistance in most environments, they are able to

maintain structural integrity without the need of additional surface coating systems or corrosion allowances – which

add to the initial costs of fabrication. Over the lifespan of an equipment or structure, stainless steels are often are

considered the most cost effective, low maintenance, long term and sustainable choice; mainly due to less need for

material replacement (new production) and also being 100% recyclable and manufactured using recycled material.

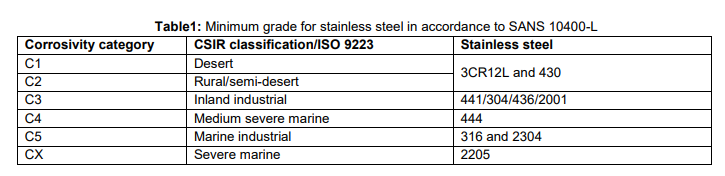

With atmospheric corrosion applications, material selection based on these considerations, may lead to the

following generalised conventional wisdom, summarised in table 1; according to SANS10400-L.

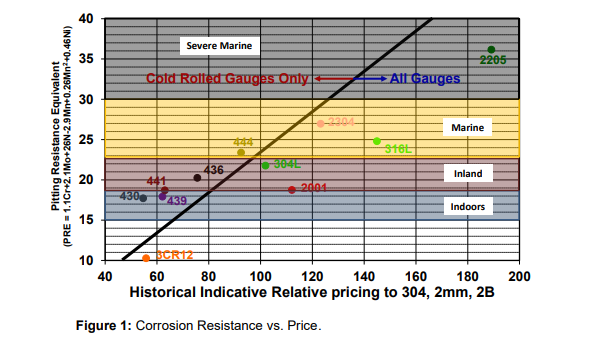

This material selection philosophy traditionally results in structures and fabrications built with good corrosion

resistance and stain resistance. But, it can be a costly solution. Figure 1 demonstrates the stainless steel options

for the various environments versus the corrosion resistance (using an empirical pitting resistance formula, derived

from our laboratory pitting test results) and cost.

In this specific case study, instead of using the conventional wisdom detailed above, an alternative approach was

taken. Note: If the material selection criteria are low corrosion resistance and structural integrity, then 3CR12 is the

solution. This is a proven low cost stainless steel solution with over 50 year track record in all atmospheric

environments.

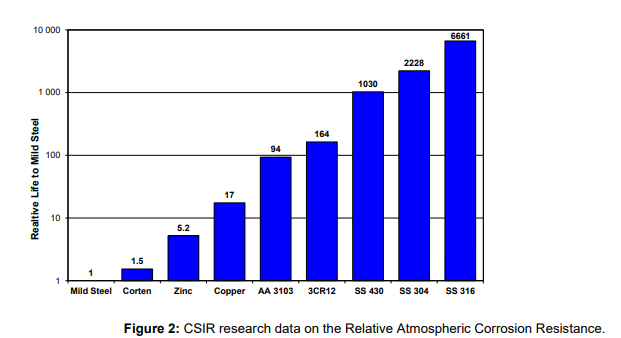

Figure 2 shows the results of a 20 year exposure programme that was conducted in various corrosive

atmospheres around South Africa. Although the actual corrosion rate of 3CR12 varied from 0.001 μm/annum in a

rural environment to 1.6 μm/annum in a severe marine environment, the relative corrosion resistance of the various

metals was quite consistent. Based on this exposure testing, 3CR12 would be expected to last about 150 times

longer than mild steel. From a structural integrity (pitting) point of view, the maximum pit depth observed in 3CR12

was in a coupon in a severe marine environment and even in this case, the pit depth was only 0.25mm after 10

years.

3CR12 is a 12% chromium-containing ferritic stainless steel, but unlike normal ferritic stainless steels, it is tough,

even at temperatures as low as -30°C - and this toughness is retained even if it is welded. Conventional ferritic

stainless steels exhibit low toughness (DBTT) and limited weldability; therefore can practically only be used in cold

rolled applications with a maximum thickness of 3mm. 3CR12 as well as the austenitic (304L and 316L) and duplex

stainless steels (2001, 2304 and 2205) are all tough, even when welded and can therefore be used in all thickness

ranges.

3CR12 – A successful case study

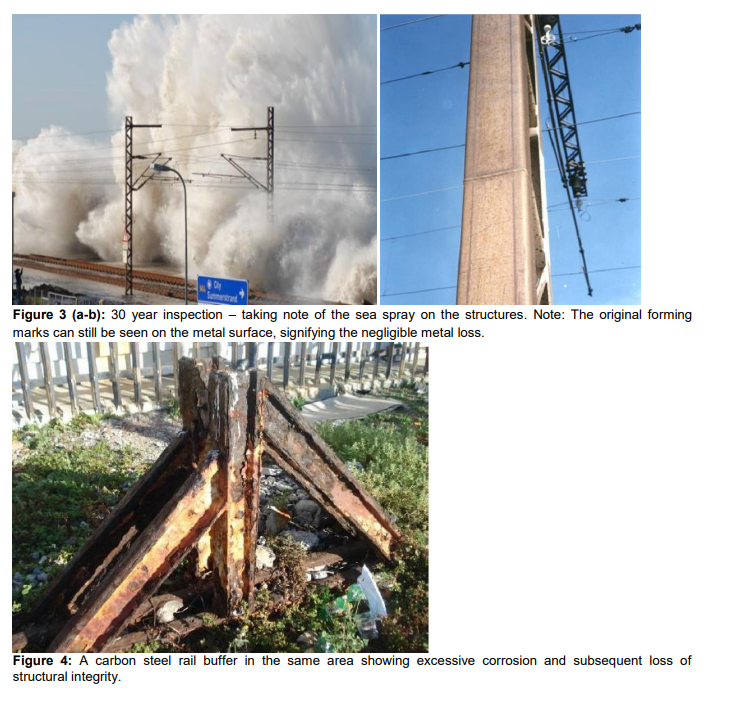

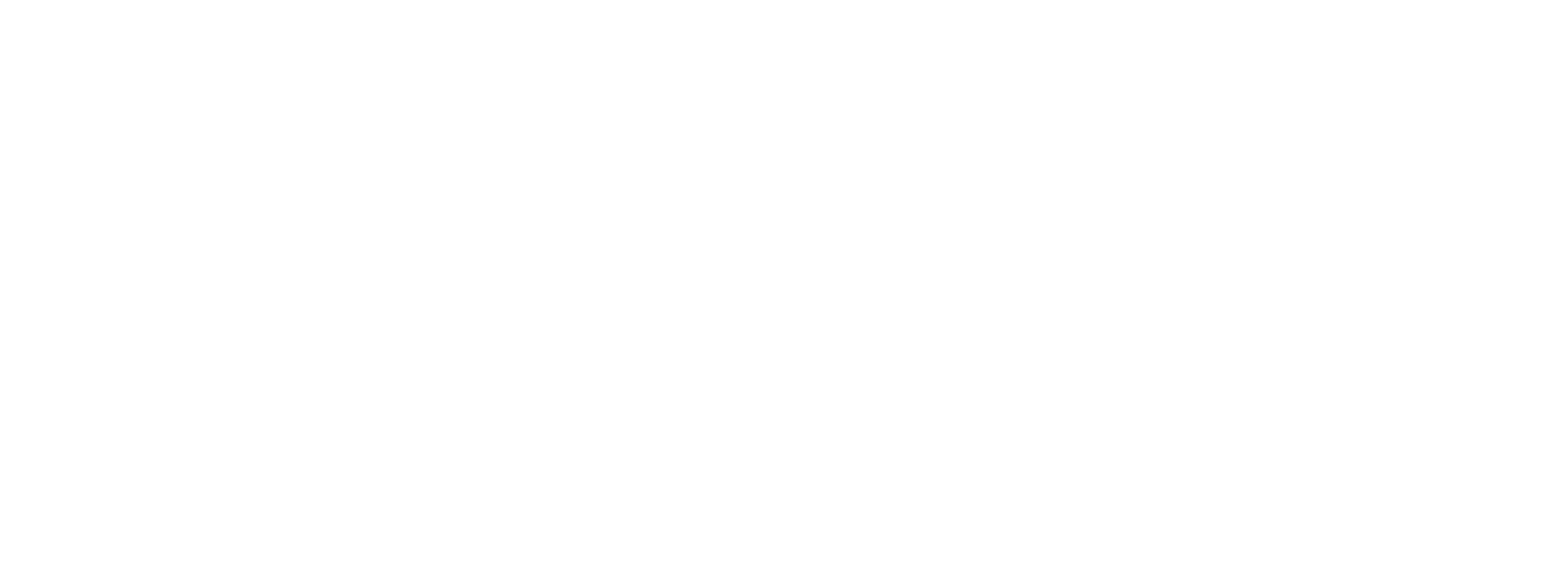

In 1982, 3CR12 electrification masts were installed for the railway line from Gqeberha (Port Elizabeth) to Barkley

Bridge; the line runs for over 30km of track from the harbour along the coast to the North End, moving inland.

During high tide and windy conditions, the masts are constantly exposed to the sea spray (as illustrated in the

pictures below). For these aggressive coastal environmental conditions, conventional galvanized or coated mild

steel was not deemed suitable for the 40-year-maintencence free life required. For this reason, the metal of

construction selected was the utility ferritic stainless steel grade 3CR12 (1.4003), a world renowned alloy invented

and manufactured exclusively by Columbus stainless. This material bridges the gap between coated carbon steels

and the traditional higher alloyed stainless steel grades.

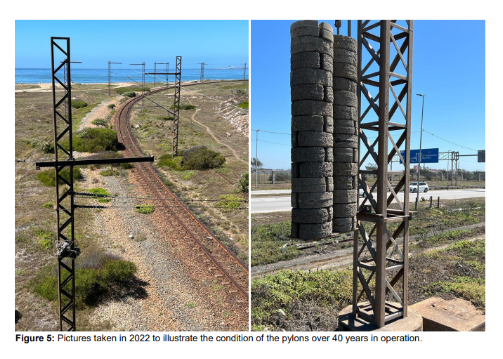

3CR12 was chosen for the lattice girder masts and beams on the line including the entire system in the harbour

area. An inspection of this original application in intervals of 14 and 30 years later found that there has been no

measurable corrosion or evidence of pitting corrosion and the system is expected to remain completely

maintenance free for at least the original intended 40 years. This proves that the longevity of the product and

minimal maintenance are very critical attributes to consider when selecting materials of construction.

3CR12 was supplied in the hot rolled and annealed (HRA) black finish. Over time, exposed to the elements, this

surface finish forms a brown patina (discolouration) – which is not corrosion. It is simply aesthetic in nature. For the

duration of this installation, the electrification masts have maintained this brownish appearance with no significant

metal loss measured. Note: In structural applications where a stained (brownish) appearance is unacceptable or

an aesthetic appearance is of importance, 3CR12 can be painted. As far as paint is concerned, 3CR12 has proved

to be a substrate which contributes significantly to improved coating performance compared to mild or galvanised

steel for numerous generic coating systems. Coated mild steel or galvanised steel suffer significant underfilm creep

and corrosion, especially in marine environments if the coating becomes damaged. With 3CR12, underfilm creep

and corrosion is avoided. 3CR12 does not show a tendency to underfilm creep.

It can thus be seen that conventional wisdom for stainless steel selection for various environments applies where

aesthetic concerns are the main criterion. If excellent corrosion resistance and structural integrity are the primary

materials selection criteria, then an alternative wisdom would suggest that 3CR12 is the obvious choice from a

performance and cost point of view.